Description :

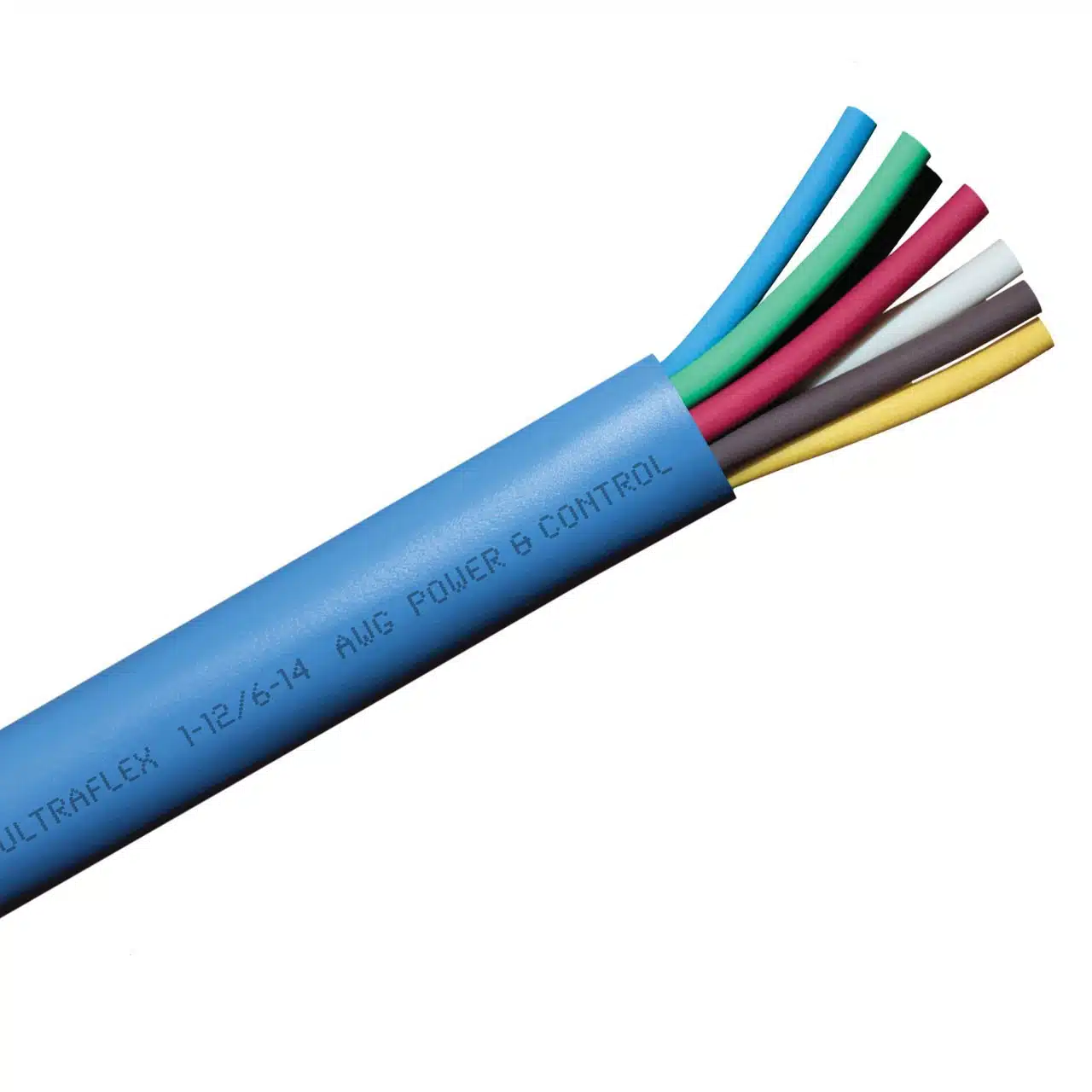

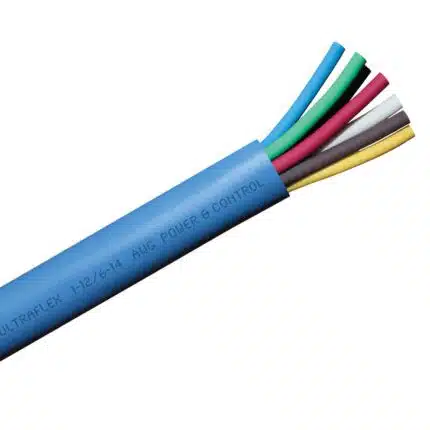

Blue Arctic Flexible Cable is an essential component in many modern technologies, providing the crucial link between electrical components and ensuring that they can move freely without risking damage to the wiring.

Unlike traditional, rigid cables, flexible cables are designed with a much greater degree of flexibility, allowing them to bend and move in any direction, often with ease.

This makes them ideal for use in a variety of applications, including machinery, robotics, and electronics, where the cables are required to bend and move to accommodate the movement of the components they are connecting.

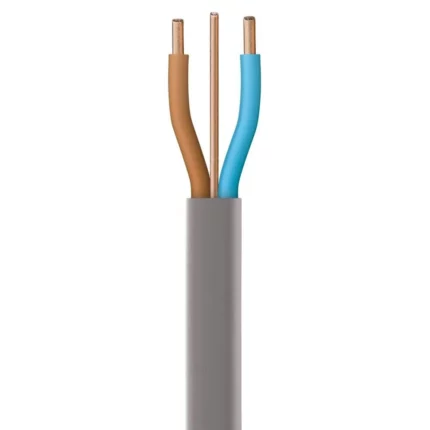

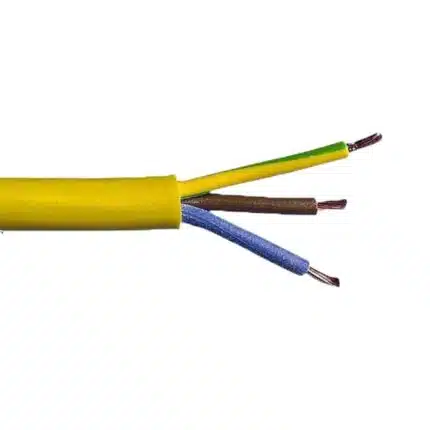

Flexible cables typically consist of multiple individual wires, each of which is carefully insulated to prevent electrical interference or short circuits. These wires are then encased in a flexible outer sheath, which is usually made of a material such as rubber or PVC. This outer sheath not only protects the wires but also provides the flexibility that makes flexible cables so versatile.

Materials of Blue Arctic Flexible Cable

Blue Arctic Flexible Cables are likely made of a combination of materials, including:

- The electrical conducting material can be copper or aluminum.

- The protective outer sheathing that safeguards the cable from external damage, moisture, and heat.

- The insulation layer acts as a barrier against electrical leakage and shocks.

- A filler material to control the cable’s flexibility and stiffness.

- Conductive metals, such as silver or nickel, enhance performance in high-temperature or high-conductivity applications.

- A bonding agent to hold all components together in a cohesive unit.

- An outer jacket layer that provides additional insulation and protection.

Construction:

- Insulation: Blue arctic flexible cables typically have a special insulation material that is designed to withstand low temperatures, making them suitable for use in cold environments.

- Conductors: The conductors are the wires inside the cable that carries electrical current. Blue arctic flexible cables usually have multiple conductors that are stranded and tinned to provide maximum flexibility and durability.

- Shielding: Some blue arctic flexible cables may have a shielding layer to protect against electromagnetic interference and ensure stable electrical performance.

- Jacket: The cable jacket is the outer layer that provides protection to the insulation and conductors. Blue arctic flexible cables usually have a durable and flexible jacket that can withstand harsh weather conditions and bend.

- Wire gauge: The wire gauge refers to the size of the conductors, and can vary depending on the desired electrical performance and current-carrying capacity of the cable.

- Oil Resistance: In some industrial applications, blue arctic flexible cables may need to be used in environments where they are exposed to oils and other chemicals. To withstand this exposure, some blue arctic flexible cables may have a special oil-resistant jacket to prevent damage to the insulation and conductors.

- Flame Retardancy: Some blue arctic flexible cables may have flame retardant properties, meaning that they will not continue to burn once the source of ignition has been removed. This can be important for safety in certain applications.

Identification –

Blue arctic flexible cables can be identified through methods such as color coding, marking, striping, labeling, and barcoding. The specific identification methods will vary depending on the manufacturer and the intended application.

These methods provide important information about the cable such as the manufacturer, product type, voltage rating, number of conductors, and other important details. The appropriate identification methods should be used to ensure that cables are installed and used correctly.

Application –

- Wiring for appliances: The Blue Arctic flexible cable is often used as the internal wiring for household and commercial appliances such as refrigerators, washing machines, and dishwashers, due to its flexibility and resistance to extreme temperatures.

- Electronic devices and gadgets: The Blue Arctic flexible cable is used in the internal wiring of various types of electronic devices and gadgets, such as smartphones, laptops, and gaming consoles, due to its flexibility and resistance to extreme temperatures.

- Robotics: The cable is used in the wiring of various types of robots, as it is able to withstand the high-speed movements and harsh environments associated with these types of applications.

- Audio and visual equipment: The cable is commonly used in the wiring of audio and visual equipment, such as televisions and speakers, due to its ability to maintain signal integrity and resist interference.

- Lighting systems: The cable is used for the wiring of lighting systems in residential and commercial buildings, due to its ability to bend and maneuver easily around obstacles and through tight spaces.

- Power tools: The cable is commonly used in the wiring of power tools such as electric drills, saws, and sanders, as it is able to withstand the constant movement and heavy use associated with these types of tools.

- Instrumentation: The Blue Arctic cable is used in the wiring of various types of instruments, such as temperature and pressure sensors, due to its ability to resist extreme temperatures and maintain signal integrity.

- Temporary electrical power systems: The cable is often used in temporary electrical power systems, such as construction sites, as it is able to withstand rough handling and rough environments.

- Automotive and marine applications: The Blue Arctic cable is used in the wiring of automotive and marine vehicles, as it is able to withstand the harsh environments and movements associated with these types of applications.

- Machinery: The Blue Arctic cable is used in the wiring of various types of machinery and equipment, including manufacturing and production equipment, as it is able to withstand the harsh environments and vibrations associated with these types of applications.

- Control panels: The cable is often used in the wiring of control panels for various types of machinery and equipment, as it is able to withstand high temperatures and resist wear and tear from frequent use.

- Portable electrical equipment: The cable is commonly used in the wiring of portable electrical equipment, such as fans and heaters, due to its flexibility and resistance to extreme temperatures.

More details :

Flexible cables are designed to offer a high degree of flexibility while still providing electrical conductivity. They are typically made from a combination of conductive materials, such as copper or aluminum, and insulating materials, such as rubber or PVC. The use of these materials allows the cables to bend and move while still maintaining their electrical properties.

Flexible cables are commonly used in applications where traditional, rigid cables would be difficult or impossible to use due to the need for movement or flexibility. Some examples include appliances, electronics, and other devices that require the movement of electrical power.

Flexible cables are also often used in challenging environments, such as in harsh industrial settings, where exposure to extreme temperatures, chemicals, and other factors can cause traditional cables to break or degrade. In these situations, flexible cables can provide a durable and reliable solution.

Additionally, flexible cables are often more space-efficient than traditional cables, as they can be bent and shaped to fit into tight spaces. This makes them ideal for use in compact devices, such as laptops and smartphones, where space is at a premium. Overall, flexible cables play an important role in modern electrical systems, offering versatility, reliability, and durability for a wide range of applications.

Reviews

There are no reviews yet.